How Is Rubber Molding Used?

Rubber molded products are used in many industries due to their durability and versatility. Clark Rubber and Plastic is a custom rubber molding manufacturer that uses certified rubber materials to create high-quality products. Here are some of the ways rubber-molded parts are used:

Automotive Industry

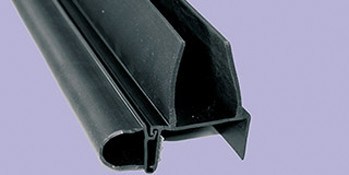

Rubber molding is used in the automotive industry to produce seals, gaskets, bushings, O-rings, and tires. Manufacturers use compression molding to produce these automotive components. During the production process, technicians place the pre-measured raw rubber material into a mold cavity. They then apply heat and pressure to compress and cure the material.

Manufacturers also use compression molding to produce engine mounts, rubber bumpers, grommets, and brake pads. Compression molding is a cost-effective method for producing high-quality, custom-designed automotive components in large quantities. This process can also be used to create cable and vibration insulators for vehicles.

Aerospace Industry

In the aerospace industry, custom rubber components boost aircraft and spacecraft’s safety, performance, and durability. At Clark Rubber and Plastic, we use rubber-molded parts to create thermal insulation materials used in spacecraft. These insulating components help protect against extreme temperature variations in outer space, maintaining a stable internal environment for equipment and crew.

Technicians employ compression and injection molding techniques to manufacture quality bellows and flexible connectors used in aircraft’s air and fluid transport systems. Compression molding also creates electrical insulation components like insulating boots and covers. These components help protect connectors and cables from moisture, dust, and electrical interference. We use high-grade rubber, such as Viton or silicone, to withstand extreme temperatures and aggressive fluids.

Consumer Industry

Rubber molding produces different consumer goods, such as footwear soles and gardening products. The process entails using different rubber materials like natural rubber, silicone, styrene-butadiene rubber, and neoprene. These materials are used with injection molding and compression molding to create rubber grips for tools, kitchen utensils, cookware, and sporting goods.

Molding techniques allow manufacturing technicians to create intricate shapes accurately and consistently. The processes produce durable rubber components like phone cases and electronic gadgets that resist abrasion, impact, and other forms of mechanical stress.

Solar Industry

In the solar industry, rubber-molded products produce various components and seals that boost the efficiency, durability, and safety of solar panels. Manufacturers utilize injection molding to create weatherproofing boots for solar panel connectors. The process is also effective for manufacturing cable management solutions, such as cable clips and holders.

Injection and compression molding techniques help create durable and weather-resistant parts for solar tracking systems. We use compression and transfer molding to create long-lasting cable entry seals for solar panels and inverters. During transfer molding, our experts preheat a rubber compound in a chamber and then transfer it into a mold cavity, where it is compressed and cured.

Choose Quality Rubber Molding Services

At Clark Rubber and Plastic, we manufacture parts using different rubber molding techniques, including injection, compression, and transfer molding. We use durometer gauges for quality control and material testing to meet the standards of consumer, aerospace, solar, and automotive industries. Contact us today for more information about our custom rubber molding services.