7 Industries That Use Plastic and Rubber Molding Services

Plastic and rubber molding services play a key role in many manufacturing processes for various industries. Each industry depends on materials made from molding processes to increase the functionality of its products. At Clark Rubber and Plastic, we manufacture high-quality materials that meet our clients’ demands. Here are seven industries that use molding services:

1. Automotive

The automotive industry uses plastic- and rubber-molded products to produce components that enhance a vehicle’s safety, performance, and comfort. These products include tires and seals to prevent flat tires while driving. Interior and exterior elements include bumpers, door panels, and interior trims. Engine parts like hoses, belts, and mounts support the engine and are heat resistant. Manufacturers also use rubber and plastic moldings for electrical wiring coverings.

2. Healthcare and Medical Equipment

Healthcare industries rely on rubber and plastic molding products to produce safe, sterile components for patient care and medical advancements. These include medical devices such as ventilators, blood pressure monitors, and diagnostic equipment. Other products, such as surgical instruments, use rubber for sterile solutions. Manufacturers use custom-molded materials to make lightweight prosthetic and orthotic devices.

3. Consumer Goods

Rubber molded products are designed for everyday household items, such as kitchen utensils and tools like silicone baking molds. Many toys are rubber-molded to make sure they are child- or user-friendly. Soles and inserts in footwear are often molded from rubber to be slip-resistant while providing comfort. Other household moldings contribute to personal care products and their ergonomic design.

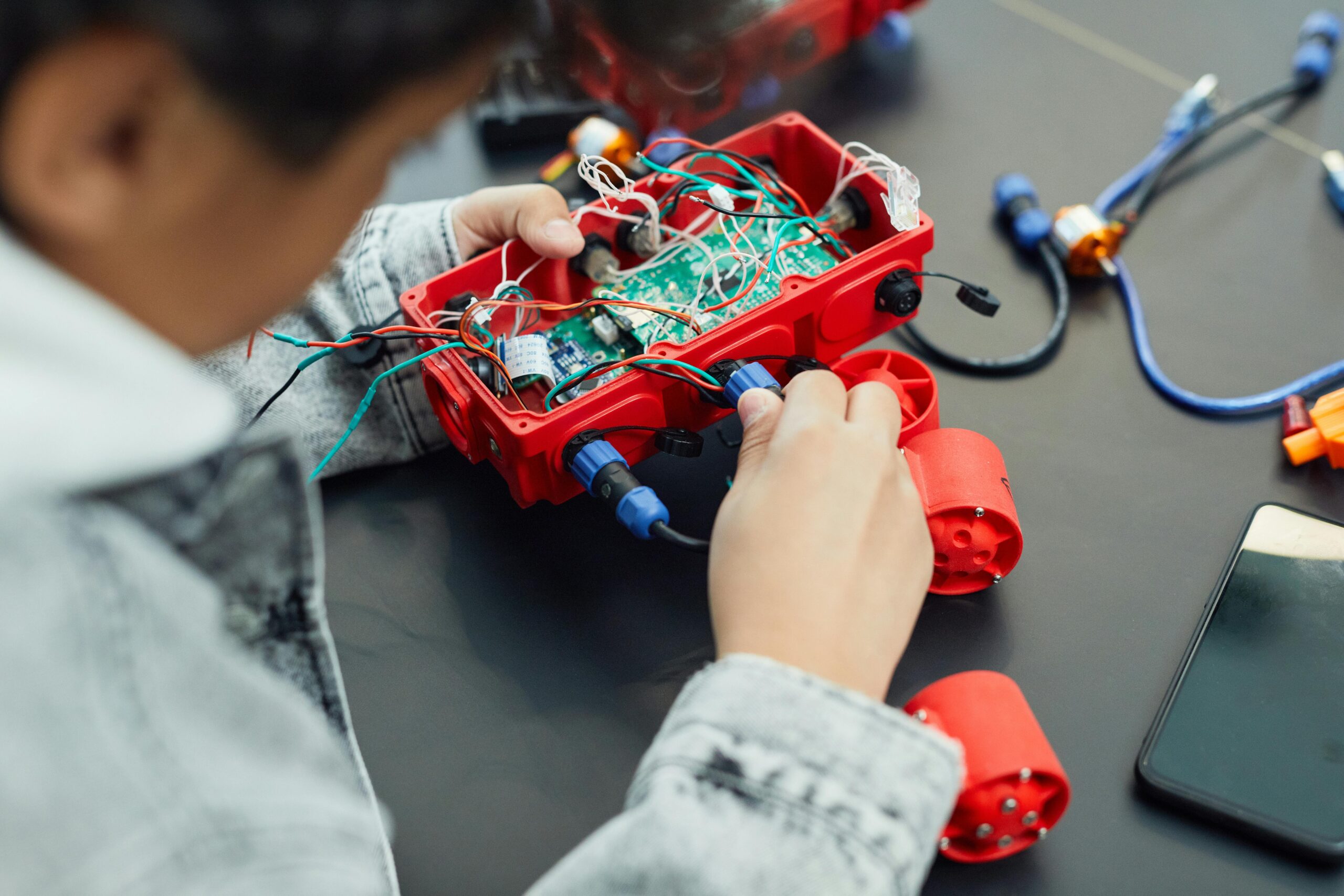

4. Electronics and Electrical

Plastic and rubber molding services create protective coverings for wires to resist environmental factors like heat and moisture. Plastic moldings are also used to make connectors, sockets, and plugs to house wiring connections and prevent the wires from touching. This can prevent sparks. Household electronic devices contain lightweight molded pieces to protect components from dust, water, and other contaminants.

5. Construction and Infrastructure

In construction, piping and fittings use rubber gaskets to seal plumbing and water management systems. Rubber molding services also create seals for windows, doors, and HVAC systems for weatherproofing and maintaining energy efficiency. Plastic and rubber are necessary to produce personal protection gear such as safety boots, gloves, and eyewear.

6. Renewable Energy

Engineers use molded rubber seals in dams and turbines to make sure they are water-tight. Rubber hoses are utilized because they can withstand extreme temperatures and pressures. Plastic framing protects solar panels from environmental conditions.

7. Aerospace

Components on aircraft, such as shock absorbers and fuel system parts, are from rubber molding services. Even items inside the aircraft, like tray tables and door handles, are built from moldings. These parts are durable enough to withstand changes in air pressure during take-off and landing.

Schedule Rubber Molding Services Today

Plastic and rubber molding services are used in industries worldwide, offering durable and lightweight materials. Our rubber molds support natural rubber, neoprene, and nitrile. From vehicle safety and medical equipment to everyday household products, molding services are integral to manufacturing. At Clark Rubber and Plastic, we deliver top-quality molding services to fit your needs. Call us today to schedule production for your next project.