6 Common Applications of Plastic Extrusion

Plastic extrusion is used to create continuous lengths of plastic products with a consistent cross-section. At Clark Rubber and Plastic, we offer extrusions that can be used in various applications and industries. Some suitable applications include solar, automotive, and appliances. Here are six common applications of this type of extrusion: 1. Solar Industry Plastic extrusion […]

What Is the Difference Between Vulcanized and Molded Rubber?

In the diverse world of rubber manufacturing, comprehending the nuances between different types of rubber can greatly benefit various industries. At Clark Rubber & Plastic, we often encounter questions about the differences between vulcanized and rubber molding. Let’s delve into these two processes to help you better understand their unique attributes and applications. Vulcanized Rubber […]

The Differences Between Extrusion and Rolling Plastics

There are two types of processes that can be used to shape raw plastic materials into a product, such as extrusion and rolling. Plastic extrusion can involve various steps, but it helps to create complex shapes while rolling. It’s mainly used to create sheets with specific thickness requirements. Knowing the differences can help you determine […]

The Differences Between Rubber Molding and Plastic Molding

Manufacturing processes like rubber molding and plastic molding play a role in the production of various products we use in our daily lives. These processes might seem similar at first glance, but each has unique characteristics. Here are the differences between rubber and plastic molding. Rubber Molding Rubber molding, or rubber compression molding, is primarily […]

How Is Rubber Molding Used?

Rubber molded products are used in many industries due to their durability and versatility. Clark Rubber and Plastic is a custom rubber molding manufacturer that uses certified rubber materials to create high-quality products. Here are some of the ways rubber-molded parts are used: Automotive Industry Rubber molding is used in the automotive industry to produce […]

What Is Die Cutting and How Is It Used by Industrial Manufacturers?

Die cutting is a fabrication technique manufacturers use to create intricate shapes from various materials. Clark Rubber & Plastic is a rubber and plastic manufacturer that provides quality die-cutting services. Our experience and advanced equipment deliver precise results, helping you get the products you need for your projects. Here is more information about die cutting […]

Natural vs Synthetic Rubber: How It’s Made and What It’s Used For

When your company needs custom rubber molding done for its projects, one of the questions you need to answer is whether you need natural or synthetic rubber. Natural rubber and its synthetic alternatives have different properties that may make them more or less suitable for your needs. Here are a few differences between natural and […]

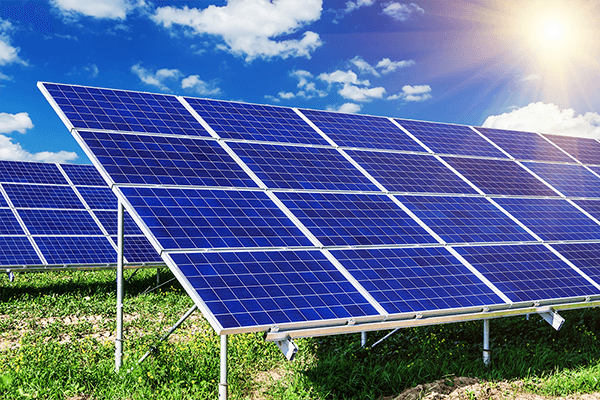

6 Solar Panel Parts and How They’re Made

A solar panel has several parts that work together to convert sunlight to electricity. Many solar panel manufacturers partner with companies that can efficiently produce the required quantity and quality of panel components. At Clark Rubber & Plastic, we provide rubber and plastic extrusion services to make components for various solar panel applications. Here are […]