Plastic Extrusion Technology at Clark Rubber and Plastic

Plastic extrusion is a manufacturing process that involves melting and shaping different plastic materials into a continuous profile. At Clark Rubber and Plastic, we make quality parts that can meet your industry standards. We use cutting-edge technology and dies to create the right plastic products. The Process The plastic extrusion process begins with our experts […]

What Type of Polymer Is Used for Plastic Injection Molding?

Plastic injection molding is a key process for automotive, healthcare, solar, and appliance businesses. The process results in custom-molded parts and components central to these industries’ operations. At Clark Rubber and Plastic, we use high-quality polymers to deliver components for projects of different complexities. Here are some common types of polymers: Polycarbonate Polycarbonate is a […]

What Types of Plastic Can Be Extruded?

Plastics are everywhere due to their simpler manufacturing requirements, versatility, and longevity. Plastic extrusion involves melting plastic to create many shapes and is commonly used for high-volume production. At Clark Rubber & Plastic, we specialize in providing custom, high-quality rubber extrusion. Here are the types of plastic that can be extruded: High Impact Polystyrene (HIPS) […]

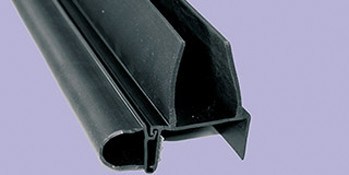

What Products Can Be Made With Rubber Extrusion?

Rubber and plastic usually make up small pieces of big machines, such as seals or insulators, but they make all the difference in terms of function. At Clark Rubber and Plastic, we work on the cutting edge of rubber and plastic extrusion. This manufacturing process that allows us to create components that fit perfectly for […]

What Is Plastic Injection Molding Commonly Used For?

Plastic injection molding is a manufacturing process used to create custom-molded products and components for various industries. The process helps produce cost-effective, high-quality plastic parts that are dimensionally consistent and identical. At Clark Rubber & Plastic, we have a dedicated team that can work on projects of any complexity and size. Below are the common […]

Why You Should Use Clark Rubber and Plastic as Your Plastic Manufacturer

Plastic and rubber materials are subject to wear and tear after exposure. To counter this, you need strong materials that withstand harsh conditions and can last for a long time. At Clark Rubber and Plastic, we provide top services as a plastic manufacturer. We make quality and long-lasting rubber and plastic materials. Here are some […]

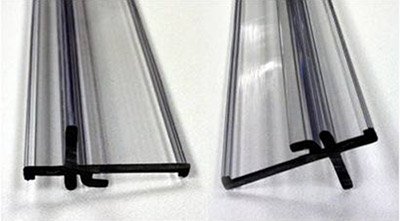

What Are the Advantages of Plastic Extrusion?

Plastic extrusion is a process that takes molten plastic and forces it through a die. This process creates profiles, sheets, rods, or tubes. The plastic extrusion process can also create thermoplastic and thermoset materials. To get the best results from extrusion, understand the different types of dies and how to use them. Here’s more information on […]

How Are Rubber Products Used in Our Daily Lives?

We see, feel, and use rubber products now more than ever. Rubber is versatile, resilient, and durable. This makes it an ideal raw material for many products. Through rubber extrusion, rubber assumes the form you desire. At Clark Rubber and Plastic, we create custom rubber extrusion products for different industries. Discover how our rubber manufacturing […]