What Is the Difference Between Vulcanized and Molded Rubber?

In the diverse world of rubber manufacturing, comprehending the nuances between different types of rubber can greatly benefit various industries. At Clark Rubber & Plastic, we often encounter questions about the differences between vulcanized and rubber molding. Let’s delve into these two processes to help you better understand their unique attributes and applications.

Vulcanized Rubber

Vulcanization is a chemical process used to enhance the properties of natural rubber. This process involves heating raw rubber in the presence of sulfur and other chemicals, which helps create cross-links between polymer chains. Vulcanized rubber offers increased strength, elasticity, and resistance to various factors like temperature, chemicals, and wear. One of the most notable applications of vulcanized rubber is in the automotive industry, where it’s used for tire manufacturing. Its durability and resistance to extreme conditions make it an ideal choice for creating tires that withstand various driving terrains and weather conditions.

Rubber Molding

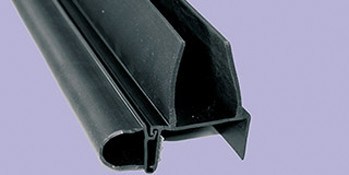

Molded rubber refers to the process of shaping rubber into specific forms and designs. This method involves placing uncured rubber into a mold cavity and applying heat and pressure to cure and shape it. Rubber molding is known for its precision in creating complex shapes and designs, typically used in the automotive and appliance industries. At Clark Rubber & Plastic, we utilize rubber molding techniques to produce parts with intricate designs and tight tolerances. Our molded rubber products find applications in various fields, offering functionality and aesthetic appeal.

Comparing Vulcanized and Molded Rubber

While both vulcanized and molded rubber have unique advantages, the key difference lies in their processing techniques and end-use applications. Vulcanized rubber enhances the physical properties of rubber, making it more durable and resistant. In contrast, molded rubber focuses on precise shape specifications for rubber to fit certain design requirements. The choice between these two rubber forms ultimately hinges on the desired attributes of the final product.

Vulcanized rubber is a viable option for items that must withstand harsh conditions and stress, while molded rubber is preferred for components needing specific shapes and contours. At Clark Rubber & Plastic, we leverage both these processes, providing our clients with tailored solutions to their industrial applications.

Tailored Solutions

Consider the example of custom automotive seals and gaskets for tailored solutions, an application used at Clark Rubber & Plastic. We often recommend vulcanized rubber for these components due to its resistance to oils and high temperatures. Our team works closely with automotive manufacturers to design seals and gaskets that precisely fit their engines or door frames, providing optimal performance and longevity. This approach in selecting and shaping rubber can meet the automotive industry’s stringent requirements.

Your Partner in Rubber Molding

At Clark Rubber & Plastic, we understand the importance of choosing the right type of rubber for your specific needs. Whether it’s vulcanized rubber or molded rubber for intricate designs, our team is equipped with the technology to deliver solutions. Contact us today to learn more about our rubber and plastic manufacturing capabilities and how we can support your industry’s unique needs.

The Differences Between Rubber Molding and Plastic Molding

Manufacturing processes like rubber molding and plastic molding play a role in the production of various products we use in our daily lives. These processes might seem similar at first glance, but each has unique characteristics. Here are the differences between rubber and plastic molding.

Rubber Molding

Rubber molding, or rubber compression molding, is primarily used for creating rubber parts and components. This method involves applying heat and pressure to form rubber materials into the desired shape. Several rubber molding processes exist, including compression, transfer, and injection molding.

Rubber casting uses natural rubber, silicone rubber, and synthetic rubber compounds. These materials are elastic and resilient. This makes them ideal for tasks that need flexible and durable items.

The material is heated first in rubber casting, placed in the mold cavity, and exposed to high pressure and heat. Pressure combined with heat vulcanizes the rubber and takes the mold’s shape. Latex molding helps to produce gaskets, tires, and seals in the automotive industry. The process is also standard in making medical devices, industrial machinery, and consumer goods.

Items made through latex molding are durable, resistant to extreme temperatures, and have superior sealing properties. Rubber casting can create complex shapes with intricate details, making it suitable for various applications.

Plastic Molding

Plastic molding is a manufacturing process used to create plastic products. Techniques used in this manufacturing process include injection molding, extrusion, and blow molding. You can use any of these methods depending on the type of plastic material and what you want the final product to look like.

This manufacturing process uses many thermoplastic materials like polypropylene, polyethylene, PVC, and many others. Each type of plastic has its own properties, which influence its suitability for different applications.

Manufacturers choose plastic material to heat to a molten state during plastic molding and then inject, blow, or extrude into a mold cavity. Once it cools and solidifies, the finished product is removed from the mold. Plastic molding is used to produce everything from packaging materials and household items to automotive parts and electronics casings.

Plastic molding processes are highly versatile and efficient. They encourage identical parts to be produced precisely and repeatedly. Plastic components are light, resist corrosion, and are cost-effective to produce.

Differences

- Rubber casting uses rubber materials, while plastic molding uses plastic polymers.

- This manufacturing process uses heat and pressure to shape rubber materials. Plastic molding incorporates the melting and solidifying of plastic materials in a mold.

- Rubber molding suits products that require elasticity, resilience, and resistance to extreme temperatures. You can apply plastic molding in various industries and product categories because it is versatile.

- Plastic molding offers versatility, repeatability, and cost-effectiveness. Rubber casting provides sealing and durability.

Use Our Rubber Molding Services

Rubber and plastic molding are two distinct manufacturing processes catering to specific applications and materials. Understanding the differences helps manufacturers and product designers select the appropriate method for their needs. Contact us today for your rubber molding needs and experience the flexibility of rubber in your everyday lives.

How Is Rubber Molding Used?

Rubber molded products are used in many industries due to their durability and versatility. Clark Rubber and Plastic is a custom rubber molding manufacturer that uses certified rubber materials to create high-quality products. Here are some of the ways rubber-molded parts are used:

Automotive Industry

Rubber molding is used in the automotive industry to produce seals, gaskets, bushings, O-rings, and tires. Manufacturers use compression molding to produce these automotive components. During the production process, technicians place the pre-measured raw rubber material into a mold cavity. They then apply heat and pressure to compress and cure the material.

Manufacturers also use compression molding to produce engine mounts, rubber bumpers, grommets, and brake pads. Compression molding is a cost-effective method for producing high-quality, custom-designed automotive components in large quantities. This process can also be used to create cable and vibration insulators for vehicles.

Aerospace Industry

In the aerospace industry, custom rubber components boost aircraft and spacecraft’s safety, performance, and durability. At Clark Rubber and Plastic, we use rubber-molded parts to create thermal insulation materials used in spacecraft. These insulating components help protect against extreme temperature variations in outer space, maintaining a stable internal environment for equipment and crew.

Technicians employ compression and injection molding techniques to manufacture quality bellows and flexible connectors used in aircraft’s air and fluid transport systems. Compression molding also creates electrical insulation components like insulating boots and covers. These components help protect connectors and cables from moisture, dust, and electrical interference. We use high-grade rubber, such as Viton or silicone, to withstand extreme temperatures and aggressive fluids.

Consumer Industry

Rubber molding produces different consumer goods, such as footwear soles and gardening products. The process entails using different rubber materials like natural rubber, silicone, styrene-butadiene rubber, and neoprene. These materials are used with injection molding and compression molding to create rubber grips for tools, kitchen utensils, cookware, and sporting goods.

Molding techniques allow manufacturing technicians to create intricate shapes accurately and consistently. The processes produce durable rubber components like phone cases and electronic gadgets that resist abrasion, impact, and other forms of mechanical stress.

Solar Industry

In the solar industry, rubber-molded products produce various components and seals that boost the efficiency, durability, and safety of solar panels. Manufacturers utilize injection molding to create weatherproofing boots for solar panel connectors. The process is also effective for manufacturing cable management solutions, such as cable clips and holders.

Injection and compression molding techniques help create durable and weather-resistant parts for solar tracking systems. We use compression and transfer molding to create long-lasting cable entry seals for solar panels and inverters. During transfer molding, our experts preheat a rubber compound in a chamber and then transfer it into a mold cavity, where it is compressed and cured.

Choose Quality Rubber Molding Services

At Clark Rubber and Plastic, we manufacture parts using different rubber molding techniques, including injection, compression, and transfer molding. We use durometer gauges for quality control and material testing to meet the standards of consumer, aerospace, solar, and automotive industries. Contact us today for more information about our custom rubber molding services.

Natural vs Synthetic Rubber: How It’s Made and What It’s Used For

When your company needs custom rubber molding done for its projects, one of the questions you need to answer is whether you need natural or synthetic rubber. Natural rubber and its synthetic alternatives have different properties that may make them more or less suitable for your needs. Here are a few differences between natural and synthetic materials and why those differences matter.

Natural Rubber

Working with natural rubber is an ancient technology that began in Mesoamerica. While modern innovations have improved the production and use of natural rubber, its versatility has made it a popular and valuable material for thousands of years.

How Natural Rubber Is Made

Natural rubber starts with tree sap. While thousands of species produce latex-rich sap, the Rubber Tree (Hevea brasiliensis) is the most important for commercial production.

Rubber producers tap trees by slashing the tree’s bark and collecting the sap. They add ammonia to the collected sap to keep it from solidifying, and then acids are added to the mixture to coagulate the rubber. Excess water is removed by pressing and drying the mixture, and then the dried rubber is baled for shipment.

Advantages of Natural Rubber

The chief advantage of natural rubber is the material’s flexibility and strength. Natural rubber also resists cutting and wear. These properties make natural rubber ideal for applications where flexibility and durability are paramount.

Synthetic Rubber

In addition to natural rubber, Clark Rubber and Plastic provides custom rubber molding with various synthetic rubber materials. While natural and synthetic materials have different qualities, they have several features in common.

How Synthetic Rubber Is Made

Manufacturing synthetic rubber begins with a petrochemical base. Oil and coal are the most common sources of these chemicals. A mixture of hydrocarbons is made from the chemical base, then refined to produce naphtha. Natural gas is added to the naphtha to produce monomers such as styrene, chloroprene, and propylene. A catalyst is then added to polymerize the material into the desired form. These polymers can then be heat treated to produce the desired properties.

Advantages of Synthetic Rubber

The main advantage of synthetic rubber materials is its versatility. While no one material can do everything, synthetic rubbers can be formulated for a variety of specialized needs. Examples of this include:

- Polyisobutylene has exceptional shock absorption properties and is commonly used in construction to protect buildings from earthquakes.

- Ethylene propylene diene (EPDM) is resistant to environmental factors. This makes EPDM a good choice for applications that need superior weather resistance.

- Neoprene is water and corrosion-resistant, making it an excellent choice for marine applications.

- Nitrile is puncture and chemical resistant, making it a superior option for PPEs.

Whether an application requires extreme heat tolerance, chemical resistance, or light tolerance, synthetic rubber meets that need.

Rubber Molding for Your Needs

Clark Rubber and Plastic offers custom rubber molding for various applications and industries. We have experience making natural and synthetic rubber for automotive, military, solar, and more applications. If you need molded rubber parts for your business, contact us for a quote.

- 1